At Canterbury Cathedral it was all fun and games dealing with high winds whilst fitting these gates. Removed in September, restored and now back from the finishers these gates look stunning. Hats off to Clayson Decorating of Uckfield who carried out all the finishing and guilding. They look superb!!!

The restoration process for this was requested to be very thorough, every repair was numbered and photographed before, during and after each repair. Once each repair was complete a report was written explaining the cause for the damage and measures taken to prevent the same cause of damage in the future. These reports and photographs were compiled to make a restoration report for The Church of England which were archived for the gates history along with any harvestable parts and tooling i had made for my restoration so that they could be reused for future restoration.

The restoration process for this was requested to be very thorough, every repair was numbered and photographed before, during and after each repair. Once each repair was complete a report was written explaining the cause for the damage and measures taken to prevent the same cause of damage in the future. These reports and photographs were compiled to make a restoration report for The Church of England which were archived for the gates history along with any harvestable parts and tooling i had made for my restoration so that they could be reused for future restoration.

At Horsmonden forge we have a real passion for restoration, combined with our passion for all things on four wheels, the restoration of this pre-war Citroen has been a space filler for the last few years. If you have visited you cant have missed it, if you haven’t visited, don’t worry, it will be coming to you!!!

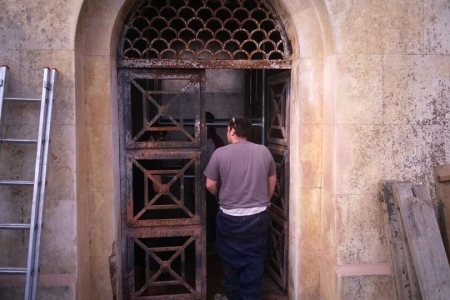

One of the largest restoration projects i have been involved with was the Rejuvenation of the Hope Family Mausoleum in Dorking. The mausoleum was buried in the 60’s and dug up in 2010. I was successful in the tender to re manufacture the front ironwork, gates and railing for the mausoleum. I was supplied with photographs of the mausoleum and had to work out material section, dimensions and construction techniques so that the newly made ironwork would be as accurate to the original ironwork as possible. All ironwork has been mortis and tenoned together for accurate reproduction of new works, the ironwork has also been fitted with the use of Lead, as opposed to resin, to keep true to the original ironwork.

I had a day on site finishing off the final touches to these gates made around 1818. It has been a real privilege to work on these gates. Damaged by vandals in the 1960’s and then buried inside the mausoleum shortly after they had not had an easy life. Works included re-seating the six large X casting that are held in with lead, mending the damage by the vandals to the drop bolts and remaking the keys for the original lock box. I was able to mend the original mechanism and make a number of keys from the internal components.

As the gates were the main form of security for the mausoleum we hand to allow to install a temporary access door which was secure enough to keep people out but removable in nature as not to cause any damage to the very soft York stone. Note the clamp style framework and wooden packers in the welding image to protect the stone. Here i am welding all the nuts and bolts shut once we were happy with the fit to prevent any one from undoing the studding.

The best part of the commission was finding a pocket of fish oil trapped in the gate from the original works in 1818. Little things like that keep you humble as to the grand scheme of things when it comes to restoring such old ironwork.

As the gates were the main form of security for the mausoleum we hand to allow to install a temporary access door which was secure enough to keep people out but removable in nature as not to cause any damage to the very soft York stone. Note the clamp style framework and wooden packers in the welding image to protect the stone. Here i am welding all the nuts and bolts shut once we were happy with the fit to prevent any one from undoing the studding.

The best part of the commission was finding a pocket of fish oil trapped in the gate from the original works in 1818. Little things like that keep you humble as to the grand scheme of things when it comes to restoring such old ironwork.

The sun crept out for a day on site reinstalling the three lanterns at Dunorlan Park. All reinstated exactly as they were when first made. Thankfully one of the lanterns had been repaired some 10 years ago which provided a guide to rebuild the other two and showed how the gas lamp door mechanism worked. Being able to work on items this old and ensure they are around for years to come is a real privilege that never fails to fascinate me.

One thing I love abut my job is the reliability of tools, (no crashing computers) the downside is how hard some of them are to find. Here we have my 3 cwt Massey, finding one of these is like finding hens teeth. Made in 1941 and at some point abandoned to rot in a field in North Durham. At the time of purchase i had no idea how it worked or how to fix it, but being so rare i couldn't not buy it. With a lot of elbow grease, research and much advice over the phone from Massey Forging Ltd i was able to strip most of it to pieces rebuild it and get her going. This machine is the keystone of the bespoke aspect of my business enabling me to forge out much larger sections (up to 6 inch square) and quantity than the more common hammers on the market.

One of my commissions for the City of London was the restoration of this pedestrian gate. Several water leaves where missing and new ones were made to match the original. Sectional replacements were made on the scrolls to maintain as much original material as possible and lastly partial repairs were made to the steel repousse motifs to maintain as much of the originals as possible.

Fitted for a client was this light well surround made to match other ironwork on site. Hot punched holes as per originals on site and small locking wedges used to hold the frame together.